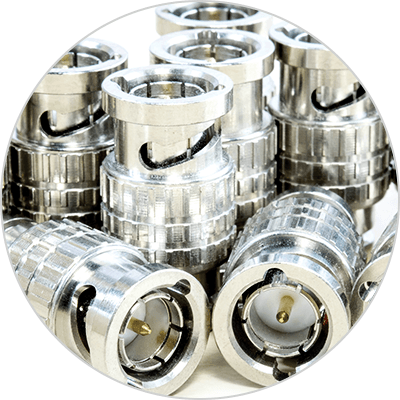

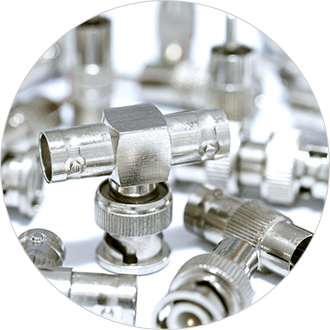

Miralloy® processes are industry’s best alternatives to silver, palladium, nickel and gold for a broad range of applications, including high frequency components and high-end decorative plating. Connectors for HF devices plated with Miralloy reach very low intermodulation values in the mobile radio frequency range. Miralloy also has important applications within health care and food service equipment.

These versatile trimetal finishes are also tarnish-free, RoHS compliant, diamagnetic, and RF-friendly. They are solderable, and weldable. Slightly leveling deposits can be achieved at all current densities. Miralloy coatings have a wide operating range.

There are several Miralloy products, each with an additive / brightener package tailored to specific applications and equipment.

Gold Miralloy is industry’s most cost-effective gold alternative for decorative plating. It was designed for use on jewelry, accessories and aircraft interiors, producing a luxurious gold-toned finish.

Gold Miralloy deposits up to 15 μm with exceptional uniformity. Average composition is 85% copper, 10% tin and 5% zinc. Deposits are mirror-like and exceptionally resistant to abrasion and corrosion. Coating hardness is 400 HV.

Miralloy 2844 has a 53-32-15 formula of copper, tin and zinc; it was developed for the decorative and jewelry industries as an answer to nickel sensitivities. Deposits develop a hardness of 550 HV; maximum coating thickness is 5 μm. High gloss can be achieved on matte surfaces by precoating articles with bright copper. Subsequent coating with gold, rhodium or other PMs is possible. Miralloy 2844 develops a hardness of 600 HV. It is suitable for both rack and barrel plating.

Miralloy 2850 has a 50-40-10 formula of copper, tin and zinc. Additives are heavy metal-free. Bright white deposits develop a hardness of 600 HV; maximum coating thickness is 10 μm. Miralloy 2850 plates at a speed that produces significant advantages in cycle time and cost. Slightly leveling deposits can be achieved at all current densities. The process is compatible with rack and barrel equipment.

Miralloy 4840 is the ultimate barrier for gold over-plate. It deposits up to 8 μm with exceptional uniformity, producing semi-gloss to gloss coatings, depending on layer thickness. Miralloy 4840 was engineered for use with barrel plating equipment.

Miralloy 2841 HS deposits up to 2 μm at .9 μm/minute and maintains the brilliance of base materials. Deposits are diamagnetic, with abrasion resistance and hardness equal to electroplated nickel. Miralloy 2841 HS was engineered for R2R equipment. Reel to reel plating electrolytes are a UIC specialty.

Miralloy 4860 has an average alloy composition of 63% copper and 37% tin, and is cyanide-free. Subsequent coating with gold, rhodium or other PMs is possible; to prevent diffusion, the minimum gold thickness over Miralloy 4860 is 0.2μm or higher. Miralloy 4860 is applied using barrel plating equipment.

Also available from Uyemura:

Dialloy has a composition of 80% tin, 20% zinc. By varying operating parameters, alloys ranging from 50/50% tin-zinc to 90/10% tin-zinc can be deposited. It is particularly effective for protecting iron and iron alloys from corrosion. Dialloy 822 deposits provide good distribution, and can be lacquered, chromated or passivated using chromium-free processes. Dialloy 822 is a ductile, low-porosity coating with excellent sliding properties; it is solderable and weldable. Common applications include clamps, bolts, lock washers and other fastener products.

For more details, or to arrange test processing, email us or contact your Uyemura representative. Miralloy 2851 and Miralloy 2841 were developed by Umicore Galvanotechnik and are available in North America exclusively from Uyemura.