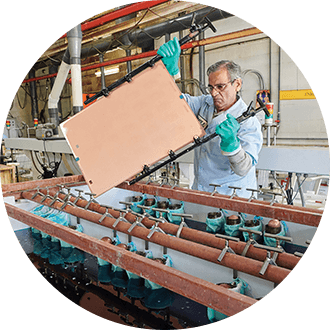

Electroless Nickel / Immersion Gold (ENIG)

Uyemura ENIG is the industry standard for uniform mid-phos EN deposits with a topcoat of immersion gold. A unique, reduction-assisted immersion process deposits higher thicknesses – 4 to 8 μin gold – in a single step, with no corrosive replacement reaction.

Deposits have a tighter grain and are more uniform than conventional immersion gold; deposits also have low contact resistance. ENIG creates a highly solderable surface that won’t discolor or tarnish; it provides exceptional electrical continuity. The nickel component forms a barrier against copper diffusion and guards against contamination of the solder during soldering and re-work. ENIG also contributes EMI shielding. This final finish process is highly resistant to corrosion, and an ideal contacting surface.

- Users of Uyemura’s ENIG process never have to waste time and resources with “dummy plating.” They also benefit from:

- A low-concentration, room temperature, chloride-free catalyst

- A bath that runs at least 10°F below the competition

- Compatibility with the newest soldermask technology

Use with the STARLiNE DASH™ Controller. This advanced electroless nickel controller is self-cleaning and self-calibrating. The controller modifies the calibration curve to compensate for by-product accumulation and maintains a comprehensive record for SPC charting.

Electroless Nickel

NIMUDEN™ NPR-8 is a mildly acidic nickel-phos plating bath. It was developed specifically for electronic and PCB applications, including HDIs and other boards with fine line circuitry. NPR-8's higher phos content (8.5% +/-1%) gives it superb corrosion resistance. For OSP pretreatment, corrosion protection can be further enhanced with increased %P in the deposit. NPR-8 has high tolerance to soldermask and dry film resist, and is compatible with lead-free solders. The bath is highly stable in continuous use; there is no risk of bridging or step plating.

Also available: NPR-4.

“RAIG” Immersion Gold

TWX-40 reduction assisted immersion gold is a single-step bath that plates up to 4-8 μin gold with zero nickel corrosion or porosity. TWX-40 is a unique process, with autocatalytic capability; this makes it the most gentle bath for nickel underlayers.TWX-40’s primary advantage is that it assures compliance with IPC 4552 rev. A. It is also valued for its ability to withstand corrosive atmospheres and light pollutant environments, and for its fast deposition rate.

Also available: TLA-77 Type S, TAM-55.

Related Products

ACCEMULTA™ MFD-5

This palladium catalyst is the activator for the electroless nickel plating of fine pattern PCBs. While traditional activators often have bridging issues with fine patterns, MFD-5 deposits more palladium on the copper, reducing the risk of skip plating and eliminating the potential for bridging between pads. Stable, chloride-free bath operates between 77-95°F; immersion time is 0.5 to 3 minutes. Needs changing less often!

MSL-17 Nanosealer

MSL-17 Nanosealer is an aqueous anti-tarnish post-treatment for ENIG and other gold deposits. It was developed for severe storage conditions, including high humidity and high pollution. This waterproof organic layer provides lasting protection from staining and corrosion. Nanosealer preserves solder joint reliability and allows thinner gold coatings to be used in many applications.

Alternative Processes

SP ENIG for Selective Plating

This modified ENIG process accommodates the processing needed for the selective plating of ENIG and OSP (organic solderability preservative). The nickel deposit is highly corrosion resistant. The gold bath produces a much tighter, lower porosity deposit.

GW Electroless Nickel with Electroless Gold for Gold Wire Bonding

In this process, the standard ENIG deposit is followed by an electroless gold step to meet the requirements of gold wire bonding.

DIG Direct Immersion Gold on Copper

Uyemura's Direct Immersion Gold process deposits a thin coating of immersion gold directly on the copper substrate. It is the best choice for highest solderability, and is ideal for "lead free" higher temperature assembly conditions. The gold coating is 1-5 μin (0.02 – 0.15 microns). DIG competes directly with OSP finishes.

TCU-38 and TCU-41 are two versions of this process that can be tailored to specific manufacturing requirements. Read the article, “Solder Joint Reliability of Gold Surface Finishes for PWB Assembled with Lead Free SAC Alloy”in the Uyemura library.