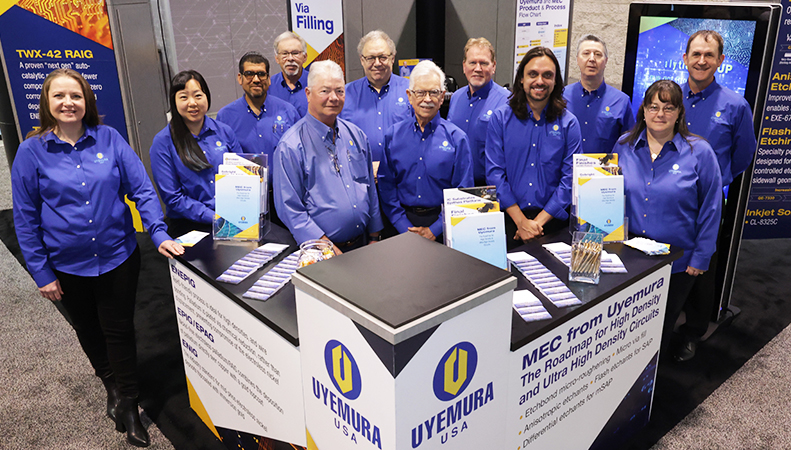

Uyemura Displays at APEX in Anaheim

Uyemura leadership from both coasts, and technical service representatives serving key technology centers welcomed customers and prospects to APEX, the electronic industry’s largest North America event.

Among the show’s most important must-sees: the MEC from Uyemura Roadmap for High Density and Ultra High Density Circuits.

Uyemura Announces Six Sigma Graduates

Dr. Patrick Valentine, Technical & Lean Six Sigma Manager and Six Sigma Master Black Belt, announces the completion of Lean Six Sigma Black Belt training by 4 members of Uyemura’s professional staff. They are: Field Service Engineer, Juan Garcia; Quality Assurance Manager, Joanna Rafalowicz; Director of Operations, David Liston, and Analytical Chemist, Matthew Natelli.

Six Sigma certification demonstrates a deep understanding of statistical analysis, problem-solving, and project management. It signifies an individual's ability to lead process improvement initiatives, drive change, and deliver measurable results. Black Belt is the program’s highest certification level.

Uyemura Announces New Sales Manager for US and Canada

Uyemura President Mark Eonta has announced the appointment of Troy McNulty as Uyemura National Sales Manager.

Uyemura USA has Joined the Printed Circuit Board Association of America

PCBAA is a consortium of U.S.-based companies that support domestic...